What are Working at Height Regulations?

The Health and Safety Executive (HSE) targets refurbishment projects, which means if your premises are undergoing any type of re-fit or construction work you may get a knock on the door!

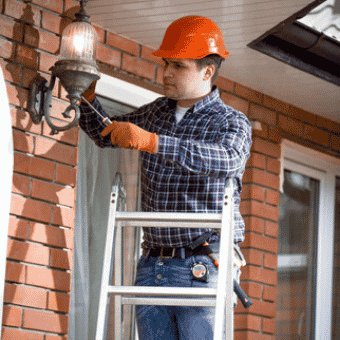

In particular, they look at working at height practices. Working at height has always been a big issue in health and safety terms and rightly so as it kills more people at work on an annual basis than any other hazardous activity. In fact, 45% of all fatalities in construction were as a result of working at height with a further 581 workers seriously injured.

Many of these accidents occur because unsuitable or poorly maintained access systems are used or there is a lack of supervisory staff who may turn a blind eye to bad working practices. Often the situations could have been avoided if the work was properly planned and supervised.

The penalties for failing to plan and manage work at height properly include:

- issue of a prohibition notice which stops work until it can be completed safely (HSE)

- fees for Intervention

- prosecution

So you can see that you are much better off planning the work properly in the first instance than being caught out by the HSE!

In this article, we explain the Working at Height Regulations and outline the hierarchy of control that should be considered when planning work at height, together with some examples of safe access systems.

The Hierarchy of Control

When planning work at height, the aim is to minimise the time that your employees spend above the ground and that when they are at a height the access system provided is appropriate for the task.

Try and arrange the work so that most of it is carried out at ground level, for example bolting together pipework running at a high level or selecting and fitting the appropriate drill bit before going up the ladder. This is far preferable to carrying out tasks unnecessarily at height. You should also carry out a risk assessment to determine the best control measures for the job. This should take into account the task to be carried out, the surrounding environment and the competency of the employee.

When selecting control measures for work at height, the priority should be to seek to use those measures nearer the top of the list rather than those at the bottom. As with all hierarchies, the measures at the top take decision-making out of the employee’s hands and therefore are more effective. They also protect the workforce as a whole rather than just protecting the individual. Similarly, measures which prevent falls in the first instance are preferred over measures that arrest the fall. The hierarchy is as follows:

Elevate Your Knowlegde With Our Working At Height eLearning Course

Ready to conquer new heights? Explore our interactive Working at Height eLearning course and take your safety skills to a new level!

1. Avoid Work at Height if possible

This may seem impossible, but you should consider how the work can be done differently. For example, if dusting ceilings you could provide an extendable feather duster that can be used from the ground or if decorating use a roller on an extendable pole.

2. Prevent People from Falling in the First Place

This takes the form of providing a safe working platform for the workforce, so scaffolding when working on the façade of a building or handrails along the open edge of a roof. It does not necessarily require large scaffolds to be used; an individual scaffold podium or mobile access equipment such as a cherry picker (suitable for the environment and terrain) could also be considered.

3. Minimising the Consequences of a Fall.

This is otherwise known as fall arrest. Fall arrest reduces the consequences of a worker falling by minimising the distance so that the worker does not hit the ground. This type of fall arrest can be achieved through the use of airbags, safety nets or, for individual workers, wearing a full-body harness and lanyard.

Air bags or crash mats are commonly used to draw alongside open-back delivery wagons where people may stand on the flatbed to offload the vehicle. Safety nets must be erected by a competent company as they must be tensioned properly; otherwise, they will sag under load. If anyone falls into the net, then the tension must be rechecked.

If using harnesses and lanyards, there are a number of safety considerations when using this equipment.

- The harness must be a full body harness as waist (climbing) harnesses will not keep the worker upright in the event of a fall.

- The worker must be trained in the use of the equipment and a rescue procedure must be in place so that the fallen person can be rescued quickly. This is because hanging in a harness has implications for the circulation of blood and there is a danger that if left hanging too long, the worker’s circulation will be affected, causing further injury or health effects.

- The lanyard must be of an appropriate length. If it is too long, it will not arrest the fall before the worker hits the ground, and if too short, it will restrict movement.

- The lanyard must be clipped to a solid anchor point that can take the weight and impact loading of the employee in the event of a fall. If the load rating of the anchor point is unknown, it should be subject to a pull-out test and the load rating determined.

Whichever control measure you select, ensure that you have properly briefed your workforce and that they are trained to use that system of work. Finally, supervise the work adequately. Do not undo all of your efforts by allowing people to walk by and ignore unsafe working practices in your workplace!

Why not check out our Working at Height eLearning course?

What the Law Says

The main piece of legislation governing working at height is the Working at Height Regulations 2005 which states that work at height should be avoided in the first instance if possible. If this is not possible then the work should be properly planned and a risk assessment carried out.

The Management of Health and Safety at Work Regulations 1999 (Regulation 3) states that employers must assess the significant risks in the workplace.

If you have a question or enquiry about health and safety, please call the team on 01452 502113 or complete our enquiry form.

Find this helpful?

Signup to our email notifications to receive alerts when we publish new blogs. We promise not to spam your inbox, you will just get a short snappy intro to Health and Safety articles we think you will love.

"*" indicates required fields

The Ultimate Fire Safety Checklist

If you’ve got a question or query, please contact our super friendly team, they will be delighted to help you!

Simply get in touch via phone or email.

Free

Resources &

Downloads

Informative. Useful. Practical.

Here at Envesca we believe that we are good at giving proactive, sensible and useful advice. Below you will find some free resources that you can download on a host of subjects that will help you and your business.

Training Available

Envesca offer a number of different training courses, which offer advice and guidance on these topics.