What Electrical Safety Checks Should I Do?

During our health and safety training courses we are often asked “What electrical safety checks should I do?” We detail the steps you should take when purchasing, using and maintaining your electrical equipment in order to remain safe and compliant.

Since 2009 fires that have started due to misuse or faults with electrical equipment have risen by one-third. Not surprising when you consider just how ingrained the use of technology is now in our daily lives.

Fire is devastating and can easily cause your business to sink or at least cripple it for a number of months. The good news is that preventing a fire from electrical faults is reasonably straight forward and it does not cost a lot of money to implement control measures.

Electrical safety starts even before you purchase electrical goods for your workplace.

You need to consider what the purpose of the equipment is and the environment in which it is to be used. Electrical equipment has different types of rating. You are probably familiar with power ratings, but there are also IP (ingress protection) ratings which tell you how good the equipment is about preventing ingress of foreign bodies such as dust and how resilient it is to the ingress of moisture. You should always choose an IP rating that is suitable for the environment in which the equipment is to be used. For example, an IP67 rated item is both dust tight and immersible in water. Once you have chosen the equipment you require make sure that it also carries a CE mark before you commit to buy.

Once you have purchased the equipment always read the manufacturer’s instructions.

Then make sure all of your employees have access to them and follow them! Many fires occur because instructions such as clearances to vents or regular cleaning and maintenance schedules have been ignored. There is no excuse for not reading instructions. It is also important to use the manufacturer supplied cables and chargers. There may be cheaper replacements available, but in the grand scheme of things buying sub-standard replacements is a false economy.

Train your staff in electrical safety.

Some good rules for them to implement are:

- Don’t leave appliances charging unsupervised for a long time or for longer than specified by the manufacturer’s instructions.

- Don’t attempt to charge a battery that looks damaged.

- Don’t cover items up when charging as they emit heat. Keep them away from flammable materials.

- Don’t leave large appliances running overnight or when no one is in the building during the day (unless they’re designed to, e.g. a fridge).

- Don’t overload sockets. Remember that outlets, extension leads, and adapters will have a limit to how many amps they can take.

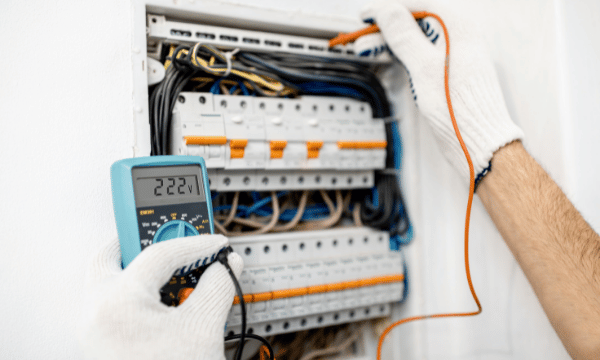

Users should also perform a visual check on equipment before each use. They should also look out for:

- burn marks or stains around plug sockets which suggest overheating.

- frayed or worn cables and wires.

- flickering lights, blown fuses, or circuit-breakers that trip for no apparent reason.

All concerns should be reported for a properly qualified electrician to investigate.

Make sure that regular inspection and maintenance schedules are adhered to.

These regular checks should include ensuring that:

- Equipment that’s used in hazardous environments (e.g. extreme weather, temperatures, or corrosive conditions) is properly protected

- Damaged sections of cable are replaced completely – don’t simply repair them with insulating tape.

- Equipment is fitted with the correctly-rated fuse.

- Proper connectors are used to join cables – don’t use connector blocks wrapped in insulating tape or splice wires by twisting them together.

- Faulty equipment is taken out of use immediately, labelled appropriately so no one uses it and inspected by a competent person.

Finally, make sure that you have RCD’s fitted between electrical items and the electrical supply, particularly on high risk items, so that in the event of a fault occurring the supply is isolated from the equipment instantly.

What The Law Says

The Electricity at Work Regulations 1989 apply to all electrical systems and equipment. You need to be aware of obvious fire risks that electrical equipment poses and understand what to do to minimise them.

If you have a question or enquiry about health and safety, please call the team on 01452 502113 or complete our enquiry form.

Find this helpful?

Signup to our email notifications to receive alerts when we publish new blogs. We promise not to spam your inbox, you will just get a short snappy intro to Health and Safety articles we think you will love.

"*" indicates required fields

The Ultimate Fire Safety Checklist

If you’ve got a question or query, please contact our super friendly team, they will be delighted to help you!

Simply get in touch via phone or email.

Free

Resources &

Downloads

Informative. Useful. Practical.

Here at Envesca we believe that we are good at giving proactive, sensible and useful advice. Below you will find some free resources that you can download on a host of subjects that will help you and your business.

Training Available

Envesca offer a number of different training courses, which offer advice and guidance on these topics.